Digital Transformation in Manufacturing

5 Mins

Updated: January 7, 2026

Published: August 7, 2025

For the manufacturing industry, the shift to smart technologies is reshaping how work gets done on the shop floor and across the enterprise. When done right, these initiatives reduce downtime, boost throughput, and elevate workforce productivity, with McKinsey estimating gains of 30–50% in key performance areas. But the real differentiator isn’t the tools themselves, it’s how people adopt and apply them.

True transformation happens at the intersection of technology, people, and process. It requires more than deploying IoT or predictive analytics. It demands aligning those tools with empowered teams and embedded workflows. Change management realizes this vision by building internal capability, addressing adoption barriers, and fostering a culture of agility. It’s how manufacturers can turn complex transformations into lasting gains.

In this article, we’ll explore how integrating change management principles enables manufacturers to implement new digital solutions and use them to drive resilience, innovation, and results.

Realizing the Benefits of Digital Transformation

In recent years, most global industrial products companies have increased digital technology investments. Manufacturers are using tools like IoT, artificial intelligence, and machine learning to streamline production, reduce waste, and improve output quality. These technologies allow companies to automate repetitive tasks and drive optimization across the value chain.

Research says that digitally enabled factories are reducing machine downtime by as much as 50 percent while realizing labor productivity up to 30 percent. It’s a great example of why integrating these technologies is critical to your digital transformation journey.

But integrating these technologies requires more than just installing sensors or software. To fully realize the benefits, organizations must also invest in workforce enablement. Because without careful planning and ensuring frontline teams know how and when to use new tools, even the best automation won’t deliver a positive ROI or reduce costs effectively.

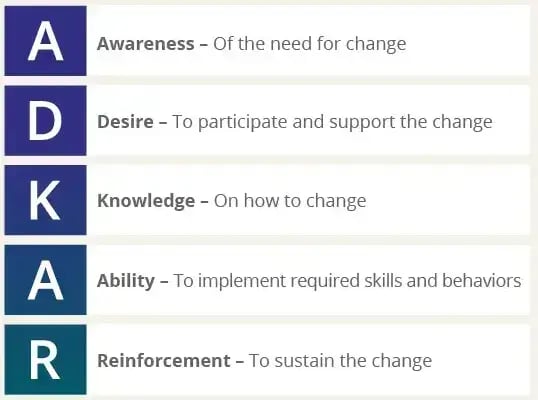

This requires aligning training programs with change management methods such as Prosci’s ADKAR® Model. Using the Knowledge and Ability elements of ADKAR, manufacturers can train employees to operate new systems while instilling in them the confidence to apply them effectively. Knowledge gives workers the technical understanding; Ability turns that knowledge into consistent, on-the-job action.

When training and tools are aligned, the impact is immediate and measurable:

- Productivity: Automation reduces repetitive tasks and frees up human workers for more value-added activities.

- Quality: Advanced analytics and digital twins allow for real-time defect detection and predictive maintenance, helping minimize scrap and rework.

- Safety: IoT devices and remote monitoring reduce risk by identifying hazards before they lead to incidents, creating safer environments and more engaged teams.

When employees are trained and empowered in leveraging digital tools effectively, they become active participants in the transformation. Each small success on the factory floor reinforces the broader strategy, creating a culture where continuous improvement is expected and embraced.

Cultural Shift Toward Agility and Innovation

As manufacturing companies adopt digital tools and reimagine their operations, they must also foster a culture that embraces change, values experimentation, and supports continuous improvement.

The most successful manufacturing organizations are rethinking how teams work on top of reimagining their system capabilities. Cross-functional collaboration and rapid iteration that encourages engineers, operators, and quality teams to test ideas, pilot new technologies, and share feedback across departments is critical. When innovation goes beyond IT or R&D, organizations respond faster to challenges and spot opportunities early.

Leadership as the catalyst for cultural change

Leadership plays a critical role in modeling this mindset. When leaders show a visible commitment to change by actively sponsoring projects, removing barriers, and reinforcing desired behaviors, they help build the Desire for change across the organization, as outlined in the ADKAR Model. Employees take their cues from leaders: if leadership embraces agility and innovation, teams are more likely to follow.

To embed this culture into daily operations, manufacturers must:

- Hold regular retrospectives to learn from mistakes and celebrate wins

- Empower employees at all levels to suggest process improvements

- Make innovation metrics (like test cycles or pilot outcomes) part of business reviews

Creating a feedback-rich environment where change is valued is necessary to embed these habits. And in a market defined by disruption, that kind of agility becomes a long-term competitive advantage.

Correlation of Sponsor Effectiveness with Meeting Objectives

Employee Engagement and Communication

Effective communication is the engine that drives employee engagement and adoption during digital transformation. To guide manufacturing teams through change, communication must be clear, consistent, and purposeful. That means answering three key questions in every message:

- Why are we changing? What business challenges or opportunities are driving this initiative?

- What is changing? How will systems, tools, or workflows be different?

- How will this impact me? What do I need to do, and how will I be supported?

When employees understand the purpose and personal relevance of change, they’re more likely to embrace it. On the shop floor, where every change can feel like a disruption, this clarity is especially critical.

It’s important to remember that communication is a two-way street. To reach workers across shifts, locations, and roles, leaders and change practitioners must use multiple communication channels, such as digital signage, mobile apps, town halls, supervisor briefings, and peer-led discussions.

Just as critical as delivering messages is listening. Feedback mechanisms like team huddles, listening sessions, and informal check-ins help organizations surface concerns early, respond with empathy, and reinforce wins (such as a smoother line changeover or reduced downtime). These interactions build trust while supporting continuous improvement of the change process itself.

Building Change Management Capabilities

To create a workforce fluent in change, you have to prioritize building change management capabilities as a core organizational skill set. One of the most effective ways to scale change is by training managers and frontline employees in the fundamentals of change management. These individuals are closest to the work and the people doing it. When equipped with the right tools and mindset, they become trusted guides able to coach their teams and model the behaviors needed for successful adoption.

Manufacturing companies need to embed change skills across functions and levels, treating them as essential as lean practices or safety protocols. This enterprise-wide approach helps normalize change as part of daily operations, not an occasional disruption.

The Prosci ADKAR Model offers a practical framework for building this capability. By leveraging the ADKAR elements of Awareness, Desire, Knowledge, Ability, and Reinforcement, teams can assess where employees are in the adoption process. For example:

- Are operators aware of why a new system is being introduced?

- Do technicians have the ability and confidence to use it correctly?

- Is leadership reinforcing the behavior changes needed?

When gaps are identified early, organizations can address them before they impact performance. Ultimately, building internal change management capabilities ensures that digital transformation isn’t dependent on a single champion or project.

The Prosci ADKAR Model

Proving the Benefits of Digital Transformation

Transformation is only meaningful if it drives real results. Otherwise, it’s just an empty expense. That’s why manufacturers must pair their digital investments with clear, measurable goals that reflect both operational performance and employee adoption.

Start by aligning key performance indicators (KPIs) with core manufacturing outcomes. Metrics like throughput, equipment downtime, and cost per unit help determine whether new technologies are delivering on their promise. If automation or analytics platforms don’t improve these bottom-line indicators, it’s time to reassess or recalibrate.

How to create effective KPIs for digital transformation in manufacturing

-

Define strategic objectives – Anchor KPIs to business goals – whether that’s increasing production speed, reducing defects, or enhancing workforce agility.

-

Balance operational and people-focused metrics – Use a mix of hard metrics (like yield or machine utilization) and soft metrics (like training completion or employee sentiment).

-

Set baselines and targets – Understand current performance before change, then establish realistic short- and long-term targets to measure impact.

-

Assign ownership – Make clear who is responsible for tracking, reporting, and responding to each KPI.

-

Build feedback loops – Use results to iterate on the approach and refine technology deployment, training, or communications.

Equally important are the people-side metrics that signal whether change is taking hold. Tracking adoption rates, training completion, and skill proficiency gives leaders early insight into potential slowdowns. If operators aren’t comfortable with a new interface, or maintenance teams lack confidence in predictive tools, those issues can quietly undercut even the best-designed systems.

Finally, treat every data point as a feedback loop. Use it to refine the rollout strategy, strengthen training programs, and target support where it’s needed most. Continuous improvement is a principle that goes far beyond the world of manufacturing. In the era of constant change, it’s the key to sustaining success no matter what arena your organization operates in.

Sustaining Manufacturing Transformation

Successful digital transformation doesn’t come from technology alone, but from the ability to blend smart tools with empowered people and adaptive processes. When manufacturers combine modern tools with a workforce that understands and embraces change, they unlock long-term competitiveness. But even the best strategy can stall without sustained focus.

That’s why building ongoing change capability is essential. With embedded skills, scalable frameworks like ADKAR, and consistent leadership support, manufacturers can navigate the industrial shifts of the future and thrive through any disruption.